GMP Annex 1 Guidelines

Good manufacturing practice (GMP) describes the minimum standard that a medicines manufacturer must meet in their production processes.

The governing cleanroom standard is ISO 14644, which is a suite of standards covering a breadth of cleanroom design and build, maintenance testing, etc.

GMP cleanrooms need more stringent levels of control than ISO cleanrooms, so the GMP Guidelines take reference from the ISO standards, adding more layers of compliance for materials, airflow patterns, occupancy states, validation states, and more.

A GMP-compliant cleanroom will also have an ISO classification, but an ISO 14644-1:2015 graded cleanroom may not qualify for a GMP cleanroom grade, as GMP Annex 1 requires extra conditions (above those stipulated in ISO 14644-1:2015) to meet the minimum requirement for medicines manufacture.

The GMP Guidelines reference the ISO standard, both with an at-rest particulate contamination level of acceptance and as an operational level of acceptance. As client’s working towards GMP compliance go through go through a formal DQ IQ OQ PQ protocol; when it comes to PQ, they will look at their process and assess that their SOPs are in-line with the amount of particulate that’s getting generated.

This process gives the opportunity to formalise procedures and reduce the risk of going out of specification when in operation.

Many industries are governed by their own regulations and through the implementation of cleanroom standards, Connect 2 Cleanrooms deliver additional levels of compliance.

Talk to the experts at Connect 2 Cleanrooms about your next project

Our cleanroom design and build specialists have experience working with customers in all kinds of industries, achieving great results time and time again. We’d love to work with you as well!

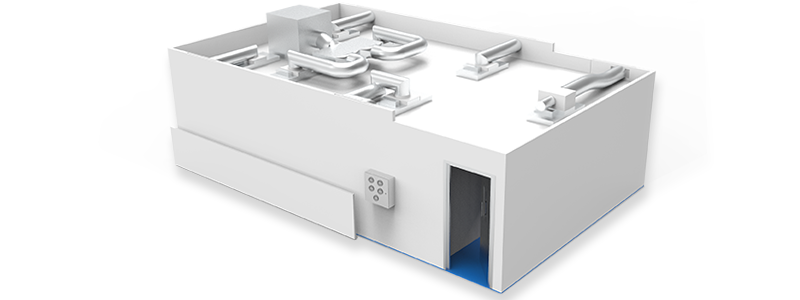

More about our cleanrooms Our GMP Cleanroom design and build service